Can transport food or pharmaceutical media with high medium requirements

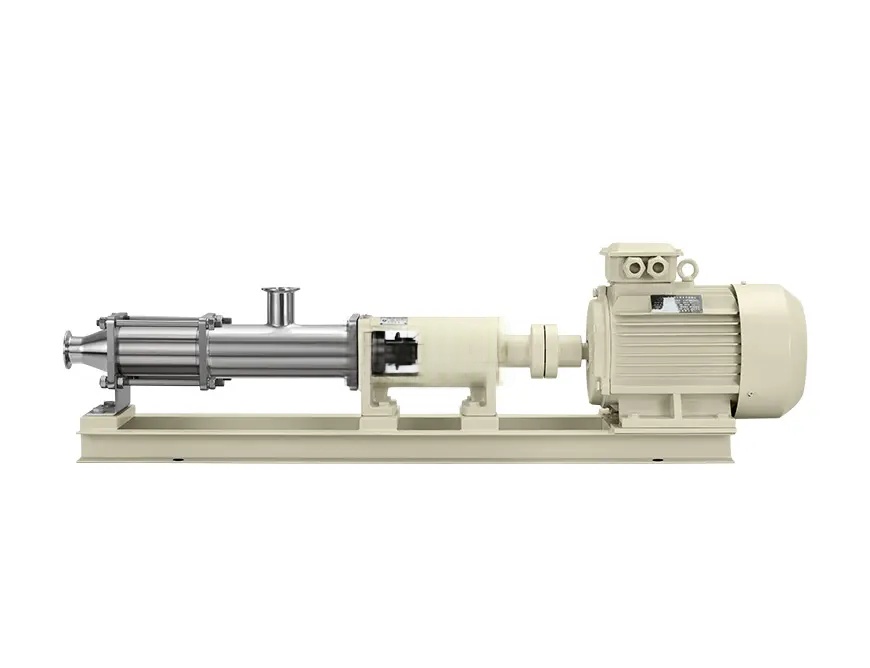

Product Introduction

Advantage

scope of application

Material comparison

Comparison of Corrosion Resistance of Four Pump Body Materials:

Cast iron<Stainless steel 304<Stainless steel 316<Stainless steel 316L

Selection of stator material

According to the properties of the liquid medium you are conveying, choose different materials for the stator

Natural rubber

Excellent wear resistance. The corrosion resistance is average, and it will swell when encountering some gasoline,

Nitrile rubber

Good oil resistance, moderate corrosion resistance, strong compatibility, and can be applied to most general liquid and fluid media.

EPDM rubber

High temperature resistance, wear resistance, moderate corrosion resistance, suitable for liquid and fluid media with high temperature and wear resistance

Fluororubber

Good corrosion resistance, moderate wear resistance, suitable for acid-base chemical fluid media with general corrosiveness

silicone rubber

Strong isolation, excellent corrosion resistance, food grade hygiene grade, suitable for industries such as food, pharmaceuticals, and laboratories,

Selection of motor types

Choose different types of motors based on the viscosity of the medium and the flow rate you require

Standard motor

gear motor

Poor liquids require the use of reducers

Continuously variable speed motor

Variable frequency motor

performance parameter

| Model | Flow | Pressure | Motor Power | Speed | Import | Export |

| (m³/h) | (MPa) | (kW) | (r/min) | (mm) | (mm) | |

| G20-1F | 0.8 | 0.6 | 0.75 | 960 | 25 | 25 |

| G20-2F | 0.8 | 1.2 | 1.5 | 960 | 25 | 25 |

| G25-1F | 2 | 0.6 | 1.5 | 960 | 32 | 25 |

| G25-2F | 2 | 1.2 | 2.2 | 960 | 32 | 25 |

| G30-1F | 5 | 0.6 | 2.2 | 960 | 50 | 40 |

| G30-2F | 5 | 1.2 | 3 | 960 | 50 | 40 |

| G35-1F | 8 | 0.6 | 3 | 960 | 65 | 50 |

| G35-2F | 8 | 1.2 | 4 | 960 | 65 | 50 |

| G40-1F | 12 | 0.6 | 4 | 960 | 80 | 65 |

| G40-2F | 12 | 1.2 | 5.5 | 960 | 80 | 65 |

| G50-1F | 20 | 0.6 | 5.5 | 960 | 100 | 80 |

| G50-2F | 20 | 1.2 | 7.5 | 960 | 100 | 80 |

| G60-1F | 30 | 0.6 | 11 | 960 | 125 | 100 |

| G60-2F | 22 | 1.2 | 11 | 720 | 125 | 100 |

| G70-1F | 38 | 0.6 | 11 | 720 | 150 | 125 |

explain:

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

market@pumpshx..com

Poly Shanshui Yicheng, No.1 Dongzhou Road, Xingning District, Nanning City, Guangxi Province, China

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.