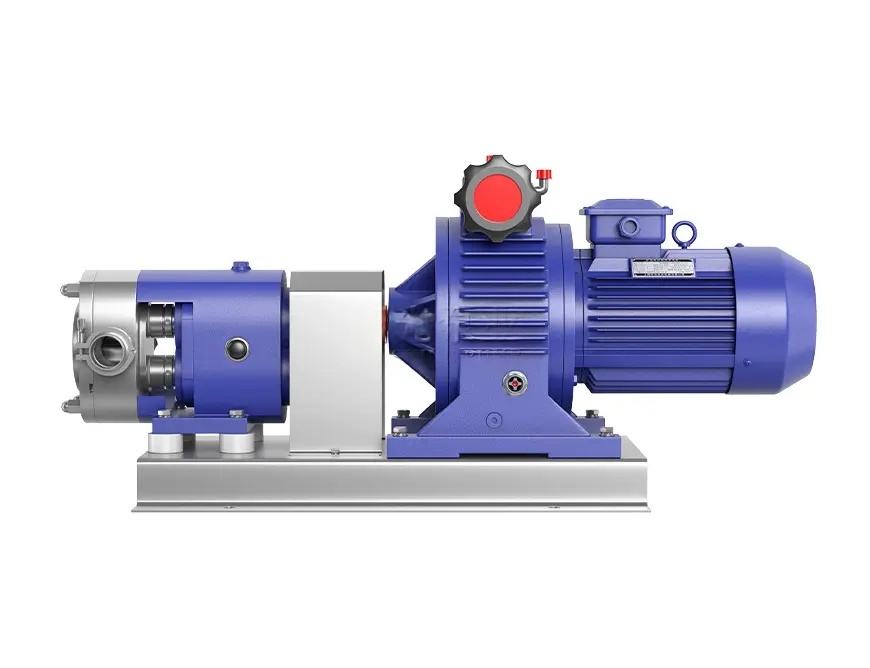

Small size, large flow rate, high head and pressure

performance parameter

| Model | Every 100r displacement |

Corresponding traffic | Pressure | Power | Caliber | Suggested speed

range |

Machine seal model |

| (L) | (L/h) | (Mpa) | (kw) | (mm) | |||

| LQ3A-3 | 3 | 300-800 | 0.3 | 0.55 | 25 | 200-500 | 20 |

| LQ3A-6 | 6 | 650-1600 | 0.3 | 0.75 | 25 | 200-500 | 25 |

| LQ3A-8 | 8 | 850-2100 | 0.3 | 1.5 | 32 | 200-500 | 25 |

| LQ3A-12 | 12 | 1300-3200 | 0.3 | 2.2 | 38 | 200-500 | 30 |

| LQ3A-20 | 20 | 2100-5400 | 0.6 | 3 | 38 | 200-500 | 35 |

| LQ3A-30 | 30 | 3200-6400 | 0.6 | 4 | 51 | 200-400 | 35 |

| LQ3A-36 | 36 | 3800-7600 | 0.6 | 4 | 38 | 200-400 | 40 |

| LQ3A-52 | 52 | 5600-11000 | 0.6 | 5.5 | 51 | 200-400 | 40 |

| LQ3A-66 | 66 | 7100-14000 | 0.6 | 7.5 | 63 | 200-400 | B45 |

| LQ3A-78 | 78 | 9000-18000 | 0.6 | 7.5 | 63 | 200-400 | 50 |

| LQ3A-100 | 100 | 11000-22000 | 0.6 | 11 | 76 | 200-400 | 50 |

| LQ3A-135 | 135 | 15000-30000 | 0.6 | 15 | 89 | 200-400 | 50 |

| LQ3A-160 | 160 | 17000-34000 | 0.6 | 18.5 | 102 | 200-400 | B60 |

| LQ3A-200 | 200 | 21600-43000 | 0.6 | 22 | 102 | 200-400 | B60 |

| LQ3A-300 | 300 | 32000-64000 | 0.6 | 30 | 108 | 200-400 | B60 |

| LQ3A-350 | 350 | 40000-80000 | 0.6 | 30 | 129 | 200-400 | B60 |

| LQ3A-400 | 400 | 45000-90000 | 0.6 | 37 | 159 | 200-400 | B60 |

keyword:Infinitely variable speed rotary pump、Transport medium pumps with high viscosity, high concentration, and particle content、

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

market@pumpshx..com

Poly Shanshui Yicheng, No.1 Dongzhou Road, Xingning District, Nanning City, Guangxi Province, China

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.