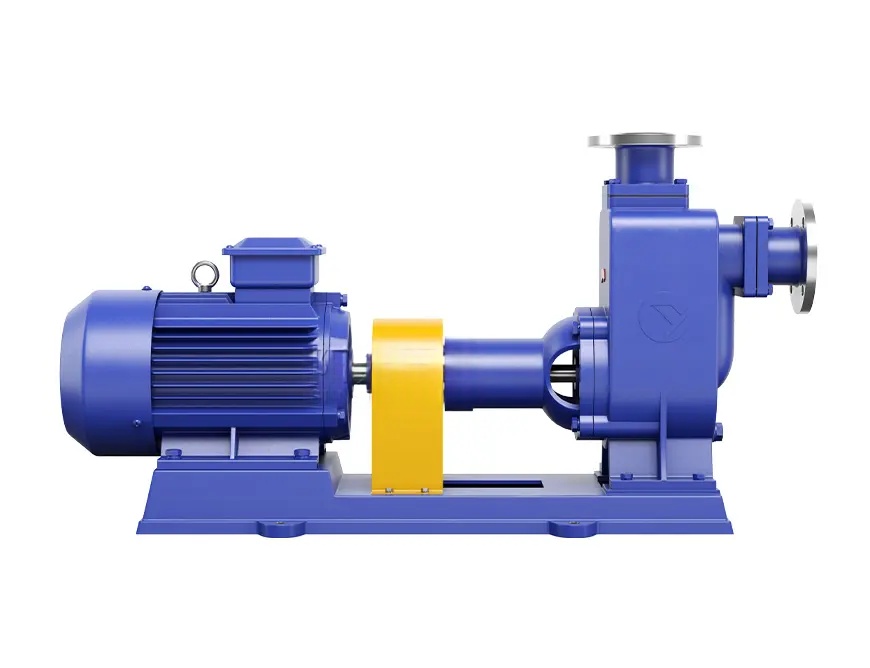

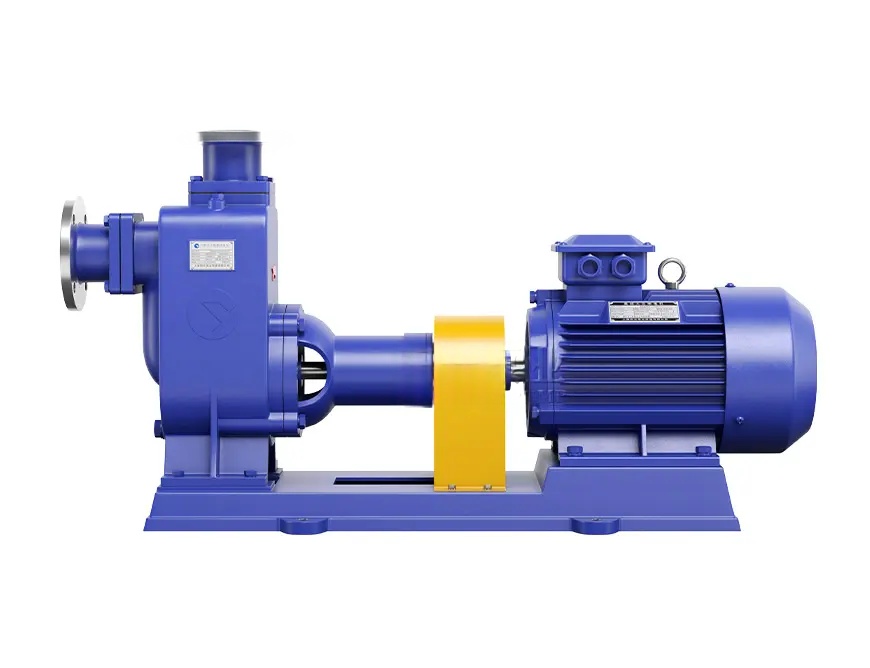

Short self-priming time, special impeller anti blocking design, capable of suctioning solids containing large particles

| No | Model | Flow | Lift | Motor Power | Whole machine weight |

Speed | Entrance and exit caliber(mm) | |

| (m3/h) | (m) | (kW) | (kg) | (r/min) | Entrance | exit | ||

| 1 | 25ZW8-15 | 8 | 15 | 1.5 | 80 | 2900 | 25 | 25 |

| 2 | 32ZW9-30 | 9 | 30 | 3 | 93 | 2900 | 32 | 25 |

| 3 | 32ZW10-20 | 10 | 20 | 2.2 | 80 | 2900 | 32 | 25 |

| 4 | 40ZW20-15 | 20 | 15 | 2.2 | 80 | 2900 | 40 | 40 |

| 5 | 40ZW15-30 | 15 | 30 | 3 | 93 | 2900 | 40 | 32 |

| 6 | 50ZW10-20 | 10 | 20 | 2.2 | 80 | 2900 | 50 | 40 |

| 7 | 50ZW20-15 | 20 | 15 | 2.2 | 80 | 2900 | 50 | 40 |

| 8 | 50ZW18-22 | 18 | 22 | 3 | 93 | 2900 | 50 | 40 |

| 9 | 50ZW15-30 | 15 | 30 | 3 | 93 | 2900 | 50 | 40 |

| 10 | 50ZW20-40 | 20 | 40 | 7.5 | 135 | 2900 | 50 | 40 |

| 11 | 50ZW20-50 | 20 | 50 | 11 | 178 | 2900 | 50 | 40 |

| 12 | 65ZW30-18 | 30 | 18 | 4 | 106 | 2900 | 65 | 50 |

| 13 | 65ZW30-18 | 30 | 18 | 4 | 179 | 1450 | 65 | 50 |

| 14 | 65ZW20-30 | 20 | 30 | 5.5 | 123 | 2900 | 65 | 50 |

| 15 | 65ZW25-40 65ZW25-50 |

25 | 40 | 7.5 11 |

142 | 2900 2900 |

65 | 50 |

| 16 | 25 | 50 | 180 | 65 | 50 | |||

| 17 | 65ZW40-25 | 40 | 25 | 7.5 | 125 | 2900 | 65 | 50 |

| 18 | 80ZW40-16 | 40 | 16 | 4 | 95 | 2900 | 80 | 65 |

| 19 | 80ZW40-16 | 40 | 16 | 4 | 170 | 1450 | 80 | 65 |

| 20 | 80ZW50-15 | 50 | 16 | 5.5 | 128 | 2900 | 80 | 65 |

| 21 | 80ZW25-40 | 25 | 40 | 7.5 | 145 | 2900 | 80 | 65 |

| 22 | 80ZW65-25 | 65 | 25 | 7.5 | 128 | 2900 | 80 | 65 |

| 23 | 80ZW80-35 | 80 | 35 | 15 | 185 | 2900 | 80 | 65 |

| 24 | 80ZW40-50 | 40 | 50 | 18.5 | 260 | 2900 | 80 | 65 |

| 25 | 80ZW50-60 | 50 | 60 | 22 | 270 | 2900 | 80 | 65 |

| 26 | 100ZW80-10 | 80 | 10 | 5.5 | 210 | 1450 | 100 | 80 |

| 27 | 100ZW80-20 | 80 | 20 | 7.5 | 246 | 1450 | 100 | 80 |

| 28 | 100ZW100-15 | 100 | 15 | 7.5 | 246 | 1450 | 100 | 80 |

| 29 | 100ZW100-20 | 100 | 20 | 11 | 260 | 2900 | 100 | 80 |

| 30 | 100ZW100-20 | 100 | 20 | 11 | 330 | 1450 | 100 | 80 |

| 31 | 100ZW100-30 | 100 | 30 | 22 | 306 | 2900 | 100 | 80 |

| 32 | 100ZW80-45 | 80 | 45 | 30 | 460 | 2900 | 100 | 80 |

| 33 | 100ZW80-60 | 80 | 60 | 37 | 480 | 2900 | 100 | 80 |

| 34 | 100ZW80-80 | 80 | 80 | 45 | 490 | 2900 | 100 | 80 |

| 35 | 125ZW120-20 | 120 | 20 | 15 | 352 | 1450 | 125 | 125 |

| 36 | 150ZW180-14 | 200 | 15 | 15 | 350 | 1450 | 150 | 150 |

| 37 | 150ZW180-20 | 180 | 20 | 18.5 | 380 | 1450 | 150 | 125 |

| 38 | 150ZW180-30 | 180 | 30 | 30 | 569 | 1450 | 150 | 150 |

| 39 | 150ZW180-35 | 180 | 35 | 37 | 600 | 1450 | 150 | 150 |

| 40 | 150ZW180-38 | 180 | 38 | 45 | 640 | 1450 | 150 | 150 |

| 41 | 150ZW180-45 | 180 | 45 | 55 | 700 | 1450 | 150 | 150 |

| 42 | 200ZW280-14 | 280 | 14 | 22 | 585 | 1450 | 200 | 150 |

| 43 | 200ZW280-20 | 280 | 20 | 37 | 744 | 1450 | 200 | 150 |

| 44 | 200ZW280-25 | 280 | 25 | 45 | 830 | 1450 | 200 | 150 |

| 45 | 200ZW280-28 | 280 | 28 | 55 | 847 | 1450 | 200 | 150 |

| 46 | 250ZW420-14 | 420 | 14 | 45 | 834 | 1450 | 250 | 200 |

| 47 | 250ZW420-20 | 420 | 20 | 55 | 939 | 1450 | 250 | 200 |

| 48 | 300ZW800-14 | 800 | 14 | 55 | 1050 | 1450 | 300 | 250 |

| 49 | 300ZW800-20 | 800 | 20 | 75 | 1200 | 1450 | 300 | 250 |

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

market@pumpshx..com

Poly Shanshui Yicheng, No.1 Dongzhou Road, Xingning District, Nanning City, Guangxi Province, China

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.