BESPOKE VALVES

Huaxiang pump are professionals in the design, manufacture and distribution of engineered valves and valve accessories for fluid management industries, covering food production, agricultural processes, wastewater management, flood defences and more.

ONE STOP SHOP

To best serve the unique requirements of our clients and their applications, we offer the option to supply a single valve, a combination of stock products, or a complete engineered valve package including ancillary equipment. Working collaboratively with our other divisions, Huaxiang pump offers cost-effective, customised, single-sourced product and service solutions that meet your specifications.

QUALITY ASSURED

We ensure the highest production standards are achieved by always investing in the latest equipment and techniques, including finite element analysis and rapid prototyping. Our advanced, in-house test facilities allow for full product testing, including hydrostatic and pneumatic pressure testing; seat testing; shell testing and more.

MADE IN CHINA

Our custom valves are designed in the CHINA by our in-house team of experienced engineers. We utilise the latest design software, continually re-evaluating products and materials to ensure that relevant industry standards regarding general quality and legal regulations are met.

What Have we Supplied?

Provide valve solutions for a tidal drainage pump station at a river mouth in the Yangtze River Delta

The pump station is located in a tributary of the Yangtze River estuary, undertaking flood control and drainage tasks for 200000 acres of farmland and three towns along the coast. The tidal drop in the engineering area reaches 4.2 meters, and seawater is prone to backflow through the pump station pipeline during high tide, causing upstream freshwater pollution and pump impeller reversal; At the same time, when the ebb tide drainage alternates with the reverse flow of the flood tide, it frequently causes water hammer effects, which have led to problems such as pipeline interface leakage and pump motor overload.

Selection and Application Scheme of Check Valve

In response to the core requirements of “high drop, strong water hammer, and backflow prevention” in the project, the technical team ultimately selected the DN1200 slow closing butterfly check valve. The key design and application points are as follows:

1、Material adaptation: The valve body is made of duplex stainless steel 2205, and the sealing surface of the valve disc is made of a composite structure of hard alloy and fluororubber, which is resistant to seawater corrosion and sediment wear, solving the problem of erosion of the valve by tidal media;

2、Slow closing mechanism: Equipped with a hydraulic driven slow closing mechanism, the closing time of the valve disc can be adjusted within 3-15 seconds. The water flow direction and pressure changes are monitored in real time through sensors, and the switching rhythm of rising and falling tides is automatically adapted to avoid water hammer caused by rapid impact of the valve disc on the valve seat;

3、Installation layout: Install one check valve on each of the three outlet main pipelines of the pump station, and reserve a 15 meter buffer pipe section between the valve and the pump station to further reduce water flow impact. At the same time, pressure gauges and inspection holes are set up before and after the valve for real-time monitoring and maintenance.

I’m Leo, the head of sales team at Huaxiang. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

Get More Benefits Since Submit The Info Form

*We respect your confidentiality and all information are protected.

Get More Benefits Since Submit The Info Form

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

Company News

Single-Phase vs. Three-Phase Panelboards

Discover the key differences between single-phase and three-phase panelboards, their applications, benefits, and how to choose the right one for your power needs.

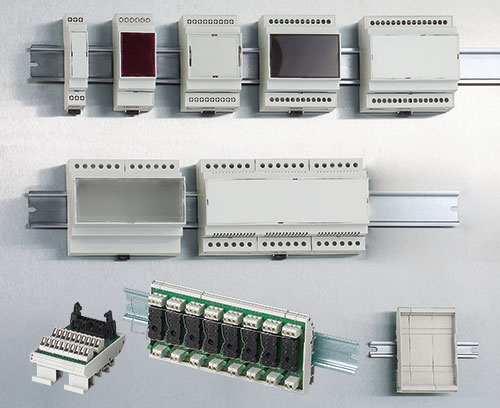

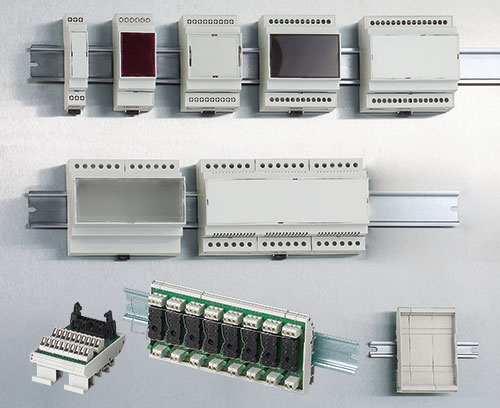

The Role of DIN Rails in Electrical Enclosures

Discover how DIN rails streamline electrical enclosures by improving organization, safety, and scalability across industrial, commercial, and smart control systems.

A Complete Guide to Electrical Panels for EV Charging Stations

Discover how electrical panels power EV charging stations safely and efficiently. Learn about components, load balancing, safety, and future-proofing tips.

Single-Phase vs. Three-Phase Panelboards

Discover the key differences between single-phase and three-phase panelboards, their applications, benefits, and how to choose the right one for your power needs.

The Role of DIN Rails in Electrical Enclosures

Discover how DIN rails streamline electrical enclosures by improving organization, safety, and scalability across industrial, commercial, and smart control systems.

A Complete Guide to Electrical Panels for EV Charging Stations

Discover how electrical panels power EV charging stations safely and efficiently. Learn about components, load balancing, safety, and future-proofing tips.

Common Uses for NEMA 4 Enclosures

Explore the versatile applications of NEMA 4 enclosures, designed for durability and protection in various settings. Find out where they fit best.